Industrial Metaverse: How Virtual Worlds Are Revolutionizing Manufacturing and Business

Introduction

The Industrial Metaverse is transforming the way businesses and manufacturers operate. By blending augmented reality (AR), virtual reality (VR), artificial intelligence (AI), digital twins, and IoT, the industrial metaverse is unlocking unprecedented efficiency, productivity, and collaboration.

As industries shift towards Industry 4.0, companies are leveraging virtual worlds to optimize operations, enhance workforce training, and streamline supply chains. But what exactly is the industrial metaverse, and how is it reshaping manufacturing and business?

In this article, we will explore:

✅ What is the Industrial Metaverse?

✅ Key technologies driving this transformation

✅ Real-world applications in manufacturing and business

✅ Challenges and future outlook

What is the Industrial Metaverse?

The Industrial Metaverse is a digital ecosystem where companies use immersive virtual environments to improve business operations, production processes, and workforce collaboration.

Key Features of the Industrial Metaverse:

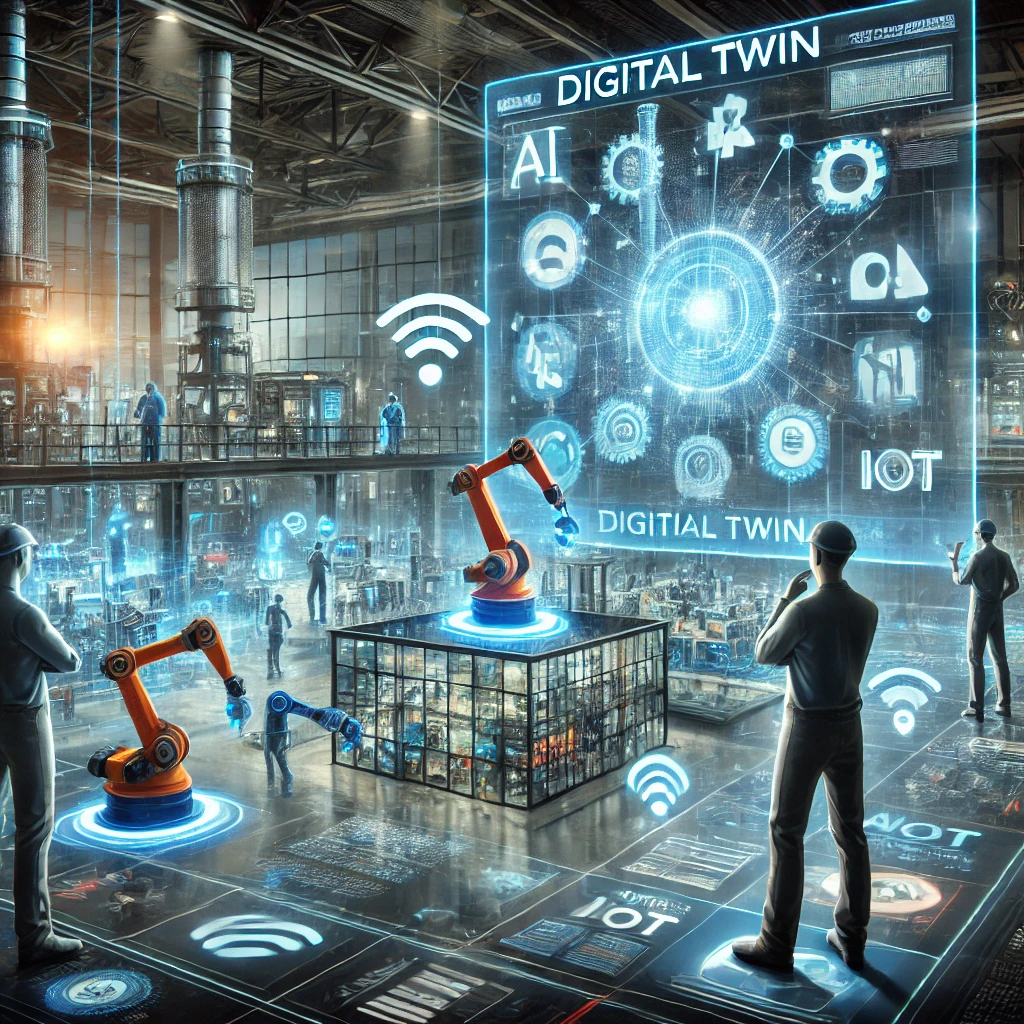

- Digital Twins: Virtual replicas of physical assets, machines, or factories for real-time monitoring and simulation.

- Augmented Reality (AR) & Virtual Reality (VR): Used for remote assistance, training, and product design.

- AI & Machine Learning: Enables predictive maintenance, automation, and smart decision-making.

- Internet of Things (IoT): Connects physical devices to digital systems, enabling real-time data exchange.

- Blockchain & Decentralization: Ensures secure transactions and data integrity in industrial operations.

With these technologies, businesses can simulate, analyze, and optimize processes before implementing them in the real world, reducing costs, risks, and downtime.

How the Industrial Metaverse is Transforming Manufacturing

1. Digital Twins: The Backbone of Smart Factories

Digital twins allow manufacturers to create real-time virtual models of factories, machines, or entire supply chains.

🔹 Example: Companies like Siemens and General Electric (GE) use digital twins to predict failures, reduce downtime, and optimize performance.

🔹 Benefit: Saves millions in operational costs by identifying inefficiencies before they occur.

2. AR & VR for Workforce Training and Remote Assistance

Traditional workforce training is costly and time-consuming. The metaverse enables immersive, hands-on training in a virtual space.

🔹 Example: Boeing uses AR headsets for aircraft assembly, helping workers visualize complex designs.

🔹 Benefit: Reduces errors by up to 90% and improves workforce efficiency.

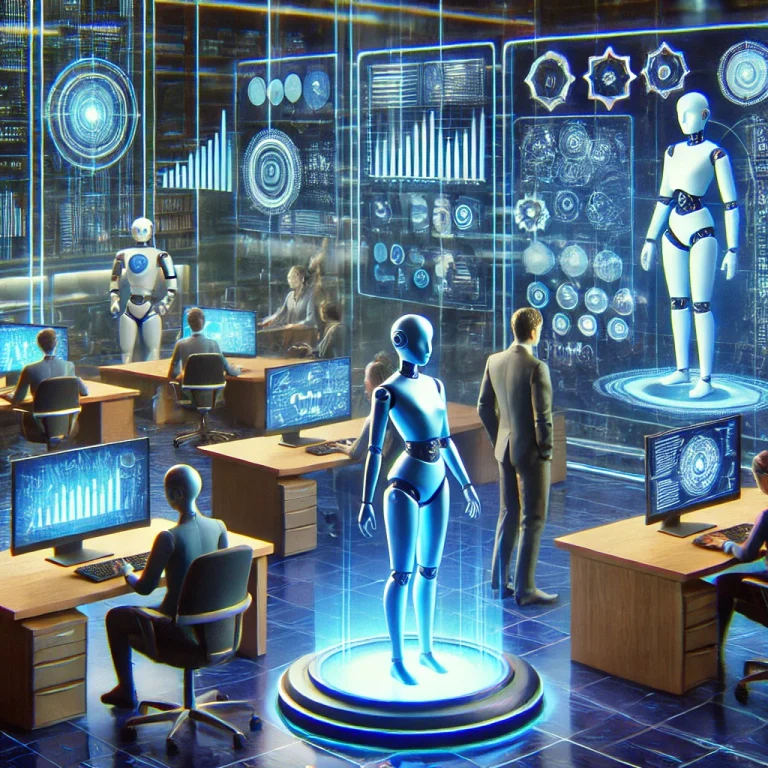

3. AI-Driven Predictive Maintenance

AI and the metaverse analyze machine data to predict failures before they happen.

🔹 Example: Rolls-Royce uses AI-powered virtual monitoring for predictive maintenance in jet engines.

🔹 Benefit: Saves millions in unplanned downtime and repair costs.

4. Supply Chain Optimization with Virtual Simulations

Companies can simulate global supply chain operations to identify bottlenecks and improve logistics.

🔹 Example: BMW uses a virtual factory to test production changes before implementing them physically.

🔹 Benefit: Increases supply chain efficiency and minimizes waste.

5. Smart Manufacturing with IoT and AI

IoT sensors in the industrial metaverse provide real-time monitoring of machines, energy usage, and production lines.

🔹 Example: Tesla’s Gigafactories leverage AI-driven automation for seamless production.

🔹 Benefit: Enables faster, smarter, and more efficient manufacturing.

How the Industrial Metaverse is Changing Business Operations

1. Virtual Collaboration & Remote Work

🔹 Problem: Traditional business collaboration is restricted by location and infrastructure.

🔹 Solution: The industrial metaverse allows global teams to work in shared virtual spaces.

🔹 Example: Microsoft Mesh enables real-time virtual collaboration for enterprises.

🔹 Impact: Reduces travel costs, improves productivity, and enhances remote teamwork.

2. Digital Prototyping & Product Design

🔹 Problem: Physical prototypes are expensive and time-consuming.

🔹 Solution: Companies can design, test, and modify products in virtual environments before manufacturing.

🔹 Example: Nike uses metaverse technology to create virtual shoe designs, reducing costs.

🔹 Impact: Faster innovation cycles and reduced material waste.

3. AI-Powered Customer Experience

🔹 Problem: Customer engagement is limited to physical interactions.

🔹 Solution: Businesses use AI-driven virtual assistants and immersive showrooms in the metaverse.

🔹 Example: Hyundai’s virtual showroom allows customers to explore cars in a 3D space.

🔹 Impact: Enhanced customer engagement and better sales conversions.

Challenges & Barriers to Adoption

1. High Implementation Costs

- Developing a full-scale industrial metaverse requires significant investment in VR/AR hardware, AI infrastructure, and cloud computing.

- Solution: Companies can start with pilot projects before full-scale implementation.

2. Data Security & Privacy Concerns

- Cybersecurity threats in virtual environments can lead to data breaches.

- Solution: Blockchain and AI-driven security protocols can enhance metaverse safety.

3. Workforce Adaptation & Skill Gap

- Employees may struggle to adapt to AR, VR, and AI-powered tools.

- Solution: Implement training programs to upskill workers for metaverse-based operations.

Future of the Industrial Metaverse

The industrial metaverse is expected to grow exponentially in the next decade, with major investments from tech giants and industrial leaders.

What to Expect in the Future?

✅ 5G and Edge Computing will improve real-time interactions in virtual environments.

✅ Quantum Computing will enable even faster AI simulations and process optimizations.

✅ Decentralized Manufacturing will allow businesses to operate across multiple virtual hubs.

✅ Metaverse-as-a-Service (MaaS) will emerge, where companies can subscribe to industrial metaverse platforms.

Projected Market Growth:

📈 By 2030, the Industrial Metaverse market is expected to surpass $500 billion (according to PwC & McKinsey).

Conclusion

The Industrial Metaverse is not just a futuristic concept—it is already revolutionizing manufacturing, business, and global operations.

From digital twins and AI-powered factories to virtual collaboration and smart supply chains, industries adopting metaverse-driven innovations are outpacing competitors and maximizing efficiency.

As the technology matures, businesses must embrace the industrial metaverse to remain competitive in the digital age.

🚀 The future of manufacturing and business is virtual—are you ready to enter the Industrial Metaverse?